Challenge:

Efficient management of hazardous chemicals is crucial for educational institutions to ensure Fire Code hazardous materials compliance and uphold safety standards for all stakeholders. Prior to implementing the Maximum Allowable Quantity (MAQ) reporting feature from Risk and Safety Solutions (RSS), three of the California State University campuses, Dominguez Hills, Northridge, and Bakersfield, each faced compliance and operational challenges in tracking chemical inventories accurately and efficiently. Despite manual efforts using spreadsheets, these campuses struggled to capture the necessary data for safety and environmental reporting as well as Fire Code compliance.

Solution:

Implementing the RSS MAQ reporting feature as part of the RSS Chemical Inventory Management solution provided clear and easy access to MAQ calculations for multiple control areas and occupancies on their campuses, allowing them to address the unique challenges of Fire Code hazardous materials compliance.

Implementation Challenges:

The campuses faced several hurdles and complications as they sought to adopt and deploy RSS MAQs.

- Achieving initial buy-in and building accountability with departments or units was a significant challenge for campuses. Identifying points of contact, hearing and understanding the concerns of faculty, and conveying the long-term safety benefits were instrumental in overcoming uncertainty.

- The COVID-19 pandemic impacted the implementation process, delaying rollout plans due to campus and lab closures. Centralized MAQ dashboards in the RSS platform allowed remote access to real-time campus data promoting efficiency and coordination during the physical-distancing protocols of the pandemic.

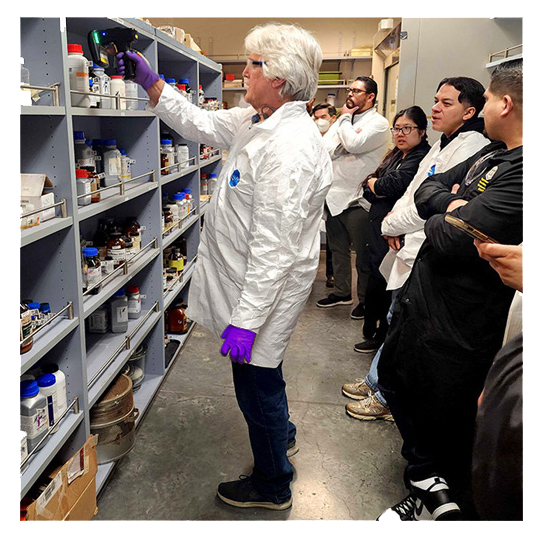

- Implementing MAQ reporting required overcoming resistance among the various hazardous materials owners on campus. Identifying and removing large quantities of expired material and compromised containers during the implementation process helped sway opinion by demonstrating the safety benefits. Empowering labs with inventory visibility, options for management, and accurate data were key to convincing holdouts.

Benefits:

Efficiency and Error Reduction – MAQ implementation has significantly enhanced efficiency and helps identify errors. The report breaks down specific hazard classes and categories, helping bring large labs and storerooms under MAQ limits.

Efficiency and Error Reduction – MAQ implementation has significantly enhanced efficiency and helps identify errors. The report breaks down specific hazard classes and categories, helping bring large labs and storerooms under MAQ limits.- Enhanced Safety Culture – Implementing MAQ integration not only improved operational efficiency but also acted as a catalyst for promoting safety culture. These campuses utilized this efficiency to strengthen safety protocols and enhance compliance, creating a sense of ownership among everyone involved. Providing support to Principal Investigators (PIs) and fostering open communication during initiatives helped forge strong relationships with the PIs. Initiating dialogues with State Fire Marshals further demonstrated proactive approaches to regulatory compliance and safety standards.

- Reporting and Audits – With RSS in place, annual reporting to the Certified Unified Program Agency (CUPA) has become notably smoother. Recent CUPA inspections at some campuses highlighted the importance of having accurate data readily available. RSS facilitates this by providing a comprehensive overview of hazardous materials on campus. Fire Code compliant inventories also help achieve accuracy on other RSS on-demand reports such as CERS.

Results:

Implementing the MAQ reporting feature resulted in significant improvements across campuses. Streamlining hazardous materials tracking allowed campuses to remove thousands of expired chemical containers and to utilize MAQ data to create Hazardous Material Business Plans, improving response times and safety for lab members and first responders. On-demand inventory data has also saved hundreds of hours previously spent hand-compiling MAQ inventory declarations for local Certified Unified Program Agencies (CUPA). These results underscore the transformative impact of MAQ reporting on hazardous materials management processes, leading to enhanced compliance, safety, and resource optimization